Metaverse Revolutionizes Manufacturing with AR, VR, and Blockchain in Industry 5.0

Metaverse: The Heart of Human-Centric Manufacturing in Industry 5.0

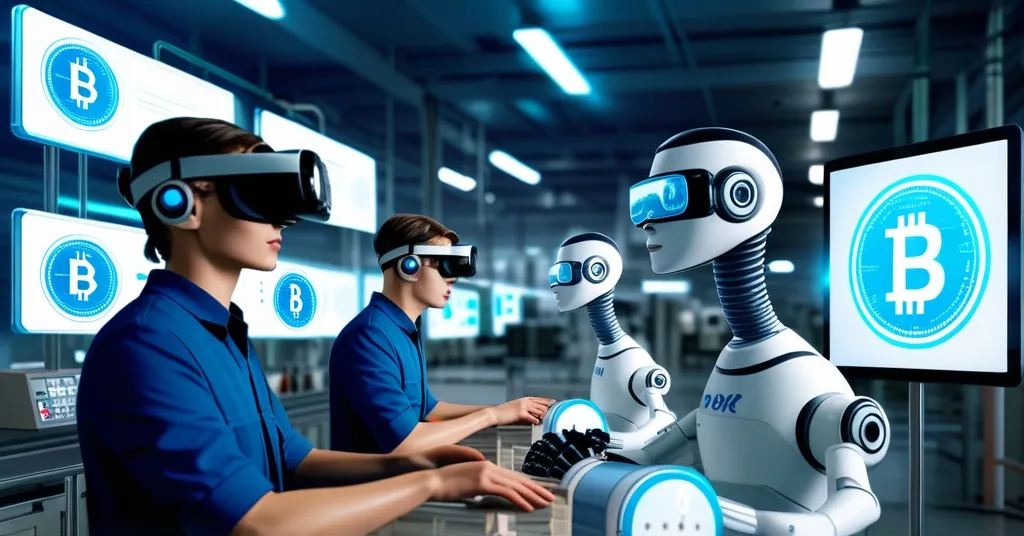

The metaverse isn’t just for gamers; it’s set to revolutionize manufacturing by bringing humans back to the forefront, ushering in Industry 5.0. This new era leverages technologies like augmented reality (AR), virtual reality (VR), digital twins, and blockchain to create intelligent factories that prioritize human-machine collaboration.

- Industry 5.0 reintroduces humans to manufacturing

- AR, VR, digital twins, and blockchain enable intelligent factories

- City University of Hong Kong develops taste simulation device

A paper published in the peer-reviewed journal Sustainability outlines how the metaverse can transform manufacturing into a more human-centric process. Augmented reality (AR) and virtual reality (VR) technologies allow workers to visualize and interact with manufacturing processes in new ways, enhancing problem identification and resolution. Digital twins, which are virtual representations of physical systems, enable real-time monitoring and predictive analysis, making manufacturing processes more efficient and less prone to downtime.

Blockchain technology plays a crucial role in ensuring the data used in digital twins remains secure and reliable. By providing immutable data storage and facilitating transparent data transfer, blockchain adds an extra layer of protection to these virtual replicas. As Sustainability notes, “The harmonisation of blockchain with digital twins adds an additional layer of protection for data composing such virtual replicas, ensuring that they remain reliable and free from tampering.”

The potential of the metaverse in manufacturing is already evident in various sectors. NASA, for instance, has utilized metaverse technology for non-destructive testing in aerospace, allowing engineers to inspect and maintain equipment virtually. Similarly, a Chinese automotive manufacturer has employed metaverse-based interactions to boost digital sales, illustrating how the metaverse can enhance customer engagement and sales.

Despite these successes, adopting metaverse technologies in manufacturing faces significant challenges. High initial and maintenance costs, along with the time and effort needed to train workers, pose hurdles. However, the potential benefits, such as enhanced human-machine collaboration and increased efficiency, make it a compelling prospect for forward-thinking manufacturing organizations. Discussions on implementing metaverse technologies in manufacturing highlight these challenges.

Adding another dimension to the metaverse’s capabilities, researchers at City University of Hong Kong have developed a compact, lollipop-shaped device that simulates taste. This device uses iontophoresis, a method to deliver taste sensations using a mild electric current, through biosafe hydrogels, simulating nine distinct flavors. This innovation opens up new frontiers in product sampling, entertainment, gaming, and even medical applications like remote diagnosis and telemedicine, enhancing the overall immersive experience of the metaverse. Applications of taste simulation devices in the metaverse are vast.

As automation continues to replace human jobs, as seen with companies like Amazon (NASDAQ: AMZN), the shift towards human-centric manufacturing in Industry 5.0 could offer a beacon of hope for the workforce. Yet, it also raises ethical questions about data privacy and potential job displacement, which need careful consideration as these technologies develop.

The ongoing integration of digital twins and blockchain with AI and machine learning suggests broader applications beyond manufacturing, extending into areas like supply chain management, energy management, healthcare, and smart cities. This dynamic and evolving landscape underscores the transformative potential of the metaverse and Industry 5.0.

“This synthesis lays the foundation for intelligent factories characterized by unprecedented interconnectivity and automation.”

“Manufacturing organizations should consider incorporating metaverse technology into their operations to harness its transformative potential.”

Key Takeaways and Questions

- How can the metaverse revolutionize manufacturing?

The metaverse can revolutionize manufacturing by integrating AR, VR, and digital twins to enhance human-machine collaboration, improve problem-solving, and create more intelligent and efficient factories.

- What role does blockchain play in Industry 5.0?

Blockchain ensures data security and reliability for digital twins, facilitating transparent data transfer and protecting against tampering.

- What are the challenges associated with implementing metaverse technologies in manufacturing?

High initial and maintenance costs, as well as the need for extensive worker training, present significant challenges.

- How does the new taste simulation device work?

It uses iontophoresis to deliver taste sensations through biosafe hydrogels, simulating nine distinct flavors in a compact, lollipop-shaped form.

- What are the potential applications of the taste simulation device?

Applications include product sampling, entertainment, gaming, and medical fields like remote diagnosis and telemedicine, enhancing the immersive experience of the metaverse.

- What are the ethical considerations of Industry 5.0?

Concerns include job displacement due to automation and potential violations of data privacy, which need careful consideration as these technologies develop.